The Foundation of Your Data Center

Sustainability follows Functionality

Welcome to the Interstitialexperience

The Time has Come

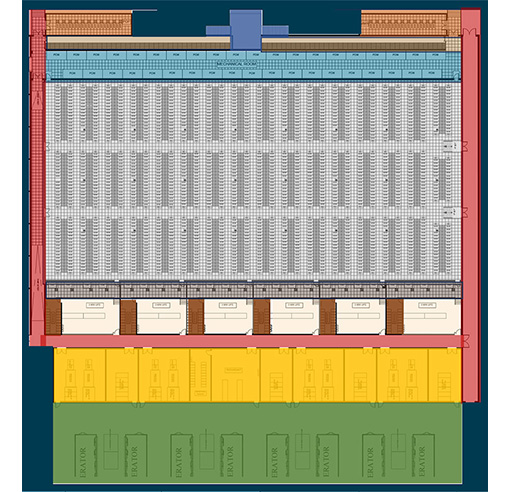

Interstitial Systems offers the only electro-mechanical distribution systemthat was designed specifically to solve the problems related to effective air, pipe and wire distribution throughout the data center regardless of its size.

We do this by creating two separate underfloor plenums that isolates pressurized air from pipes and wires. This provides precision air cooling for the servers and a separate upper utility plenum for simple distribution and reconfiguration of power, structured cabling. and liquid cooling pipes without disturbing airflow.

Imagine

The Electro-Mechanical Distribution System that Changes Everything

Reliable, simple distribution of air, power, cabling, and liquid cooling lines is a functional solution for building better data centers.

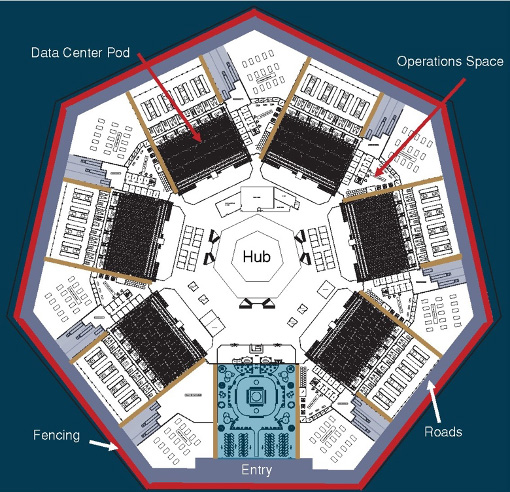

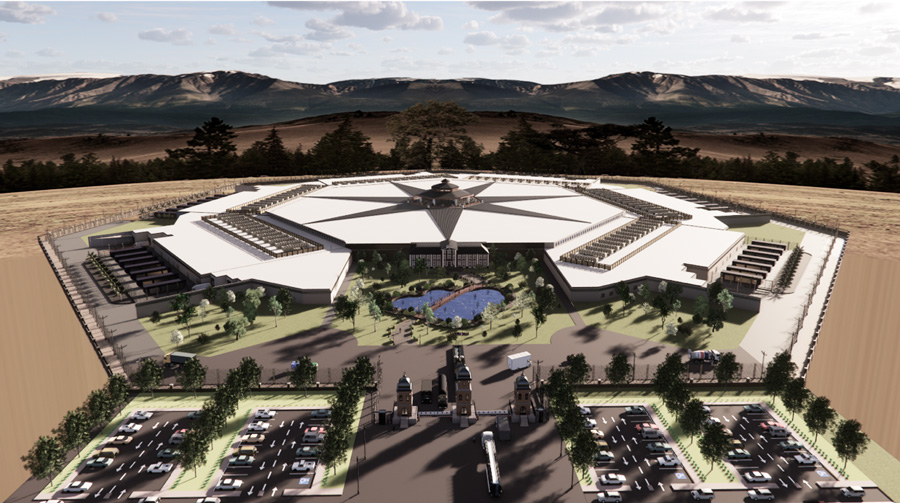

This 150 MW streamlined data center campus has 6 Pods with 1,600 cabinets in each. The Heptagon configuration creates a central atrium for support services. This design reduces the land required by 40%, and there's many additional features. It’s easily adaptable to a variety of configurations, number of buildings, and MW. Visit our Library and download document 17 and 18 for more information.

OUR LOGIC

Why Interstitial Systems

This unique, simple design separates cabling and piping from airflow.

We split the underfloor into two separate levels, the top for wires and piping, the bottom for air, making a functional, efficient electro-mechanical distribution system.

1

Easy Wire Management

- Put all the wiring under the floor where it belongs—faster, cost effective installation

- No need for plenum rated cables

- Change, add, or relocate wiring without disrupting airflow

2

Simple Piping Installation

- Install all chilled water piping and/or hoses in the upper utility plenum

- Underfloor piping is a best practice and is code compliant

- Eliminates risk of water leaks mixing with IT Equipment

- Piping can be installed and reconfigured without disturbing airflow

3

Dependable Air Distribution

- Effective cooling all the way from the bottom to top of the cabinets.

- Regardless of room size, configuration, or cabinet loads—up to 50 kW

- Effective Redundancy

- No need for costly containment

What isInterstitial?

In architectural design, an interstitial space is an intermediate area located between floors, specifically created to house a building's essential electrical and mechanical systems. These spaces conceal vital infrastructure, making them easier to access, maintain, and renovate—extending the building's lifespan.

Interstitial Systems' approach is a simpler and more streamlined way to achieve the distribution of air and electrical services. We install two interstitial spaces over the existing slab, creating an electro-mechanical distribution system that accommodates all necessary air, piping, wiring, and cabling for the effective operation of your data center.

Planninga new data center?

Visit our library page to read various documents with helpful information regarding the value of Interstitial and how effective, and efficient distribution of air, pipes, wires and cabling will improve your data centers functionality and make it more sustainable.

Keep in mind this >100-year-old phrase by the “Father of Skyscrapers” architect Louis Sullivan, which has been adopted by architects world-wide to this day: “Form follows Function”

Interstitial Systems adheres to this and has coined the phrase: “Sustainability follows Functionality”